The transformation from drawing-based old design system to 3DCAD-based new system

The present shipbuilding industry is transfering from traditional drawing-based design system to 3DCAD-based new design system. (These two systems, see Appendix 2)

The scale of whole shipbulding system is so large and so complex that this transformation needs much time and many stages. Especially, upper functional design sections need much more time to be restructured because they are influenced by many traditional methods, knowhows, experiences, and outer limitations like class-rules, various standards and ship-owner's conveniences.

According to my thinking, there are the three transformation stages roughly, or the five stages in detail as below:

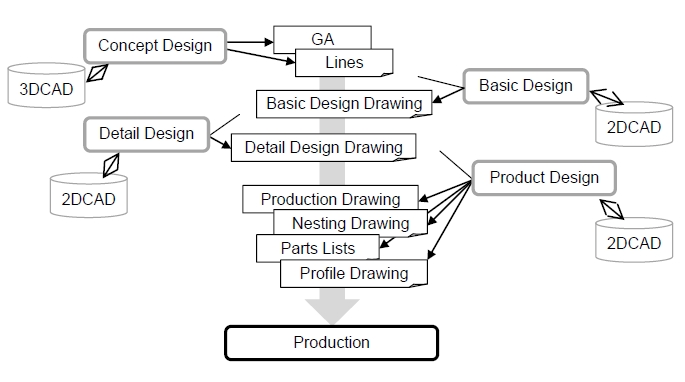

(1) Traditional drawing-based design system

This system is tipical and traditional ship design system. The various drawings consists the information database of the whole ship matters. Each engineer makes his drawings at every design stage, with the result that the all necessary informations are build up smoothly. Although each design section uses 3DCAD or 2DCAD, the formal output data is published as a drawing.

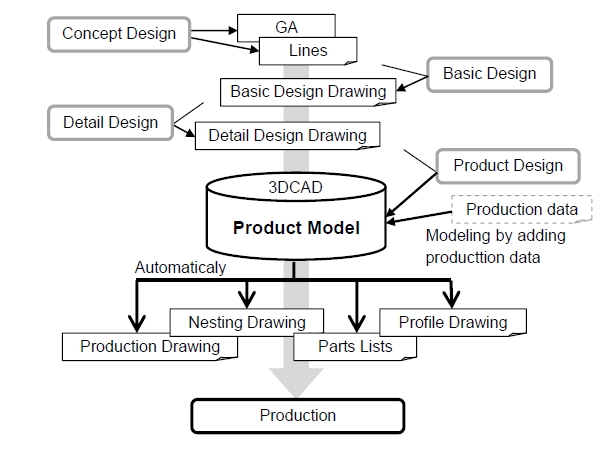

(2) Make the product data by 3DCAD

Upper functional design sections are kept up, and the product data are made by 3DCAD.

Many shipbuilders are in this stage now.

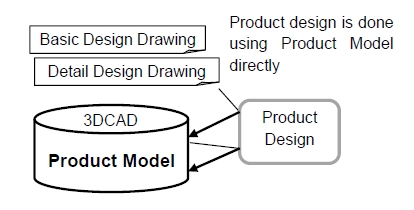

(2.5) Make the product data more efficiently

The product design is done with product models directly. 3DCAD supports the product design by the functions, for example, that various product data, like bevel shape, notch, corner shape, etc, are made by the building strategy automatically.

Because the product design that puts emphasis on 3D shape and weight, it can apply the advantages of 3DCAD more effectively than the upper functional design.

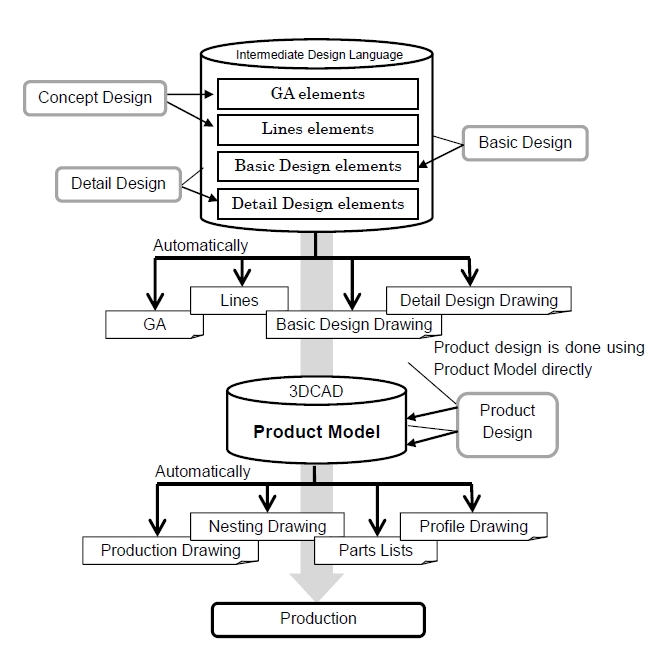

(3) Degitalize the functional design elements by Intermediate Design Language

The functional design is processed with common degitalised Intermediate Design Language instead of drawings. The Indermediate Design Language is structured to make the common resourse maximum by considering the existing work division, the tools, the methods and the environment. Thus, the reuse of the information in the functional design progresses as wide as possible. LEAPS of U.S.Navy is the representative example of this.

Some shipbuilders use 3DCAD in the functional design area instead of Intermediate Design Language. In this case, the 3DCAD in the functional design is separated from the one in the product design.

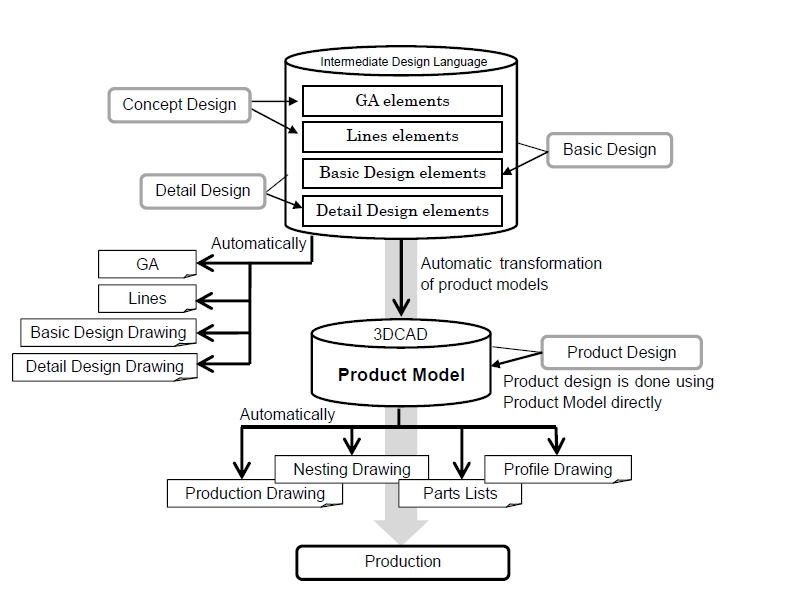

(3.5) Automatically make the product models from the Intermediate Design Language

Although the functional design and the product design are separated yet in this situation, the automatic data transfer from Intermediate Design Language to the product models eliminates the modelers who mediate between the functional design and the product design. This elimination of the modelers will improve the efficiency of the works and the accuracy of the data.

The design element structure, that makes design detailed by purely additional elements in both functional and product designs, will make the parallel work and correction easier.

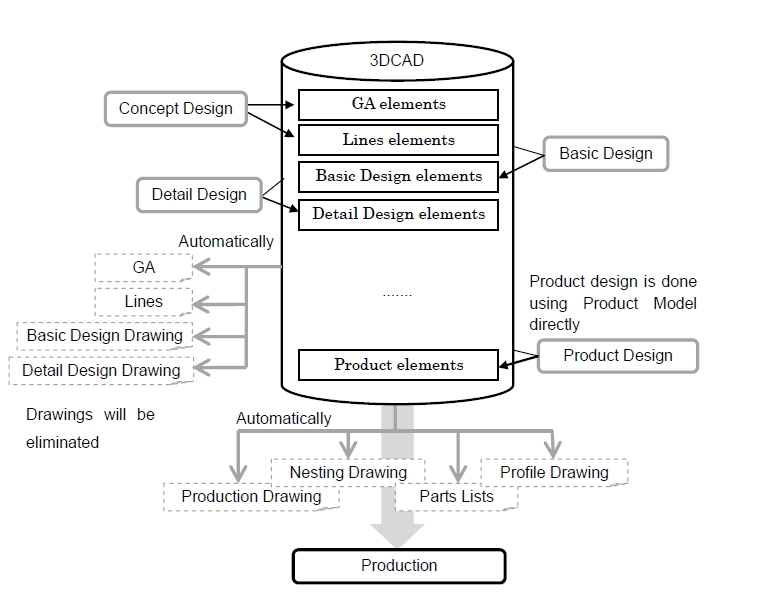

(4) All-in-one 3DCAD world

The all shipbuilding works are done on the one 3DCAD in this situation, and this is the final goal. The direct extraction of necessary informations from database will eliminate the drawings.

Altough many present commercial 3DCADs consider the application in this stage, no 3DCAD achieves this goal really.

The necessary functional conditions for the ideal 3DCAD progress

There are three conditions that are necessary to progress to the ideal 3DCAD.

(A) For the product design on 3DCAD: (2) -> (2.5)

The function that the additional productional information, like the conditions of building and fabricating and the productional standards, decides the final part shape automatically is necessary. Thus, this divides the product design from the functional design perfectly and makes the production design to be self-contained on the productional 3DCAD.

Without this function, we must finish the product design as the product drawings practically and make modelings by tracing them. This is not smart.

(B) For the automatic transforming function of the product models: (3) -> (3.5)

The function that transforms the Intermediate Design Language to the product model automatically is necessary. At the same time, the data structure that is close to the Intermediate Design Language is required for the 3DCAD in order to realize this function smoothly.

(C) For the all-in-one 3DCAD: (3) -> (4)

The environment that the multi workers can develop the same one part asynchronously is necessary. The new design structure that the all design elements are represented smartly in every design stage is required for this.