Drawings and 3DCAD

1. Introduction

For long time, human has been making products by the drawing-based design system, and this is the same for ships. This design system makes large influence on design organization, design culture, design method, production process and shape of product itself. The design system is a very important matter for thinking about products.

Recent development of computers lets human to present information not only on papers but also on electric data. The convenience of this electric data drives the design knowlege from papers to electric data, and one of those results is the appearance of 3DCAD in place of Drawings. And much high-ability database and network in these several years let us to treat much more information in much shorter time that we couldn't imagine before.

But, as the valume of available information is increasing quickly, human is now faced with a new problem, "Complex System". The increasing valume of information makes not only the figure number of value but also the number of relations between informational elements.

Until now, the technical limitation also naturally saves the valume of information that one person treats. And at the same time, design organization, design culture, design method, etc, intentionaly limit the valume of one person's information in order to let him to treat information efficiently. Now, as the technical limitation is getting looser and looser, the necesity of new construction or re-structure of the design system optimized with new environment must increase. But it will be very difficut work because we are binded with various exsisting matters like other system, culture, method and knowhow.

Anyway, for efficient immigration to new system, it's necessary to recognize both where we have been on and where we are going to. The wrong recognition of existing method and new one makes us to lose ourselves and to waste valuable resouses.

2. Design System of Drawings

The drawing-based design system, that is mainly used in present ship-design work, has been made from the design of sailing ship for hundreds years. The present form of drawing-based design system had been finished in the terms when an iron ship was invented on the end of 19th, and from then, there have been few changes like a invention of construction drawings.

The types of drawings of Hull design are below;

- General arrangement drawing, etc

- Lines drawing , etc

- Basic design drawing (Key plan)

- Detail design drawing (Yard plan)

- Construction drawing

- Nest drawing, Part drawing, etc

Every design layers has various type drawings. Each drawing presents a part of whole product. And whole product can be presented by collecting whole drawings.

Main characteristics;

- As drawing is develope more detailed, size is getting smaller and number is getting more.

- Drawing is a module of both design and work. All design works are done by unit of drawing and this means that all work flows are managed by drawing, too.

- Every element of drawing, like size, type, object range, method of presenting and conbination, have been optimized for long time.

- The direction of referential relation between drawings is only one direction from lower design level to upper. There is a clear direction of relation between different discipline drawings like Hull and Outfit.

- The refering value and shape for other drawings don't re-define in new lower drawing in parallel. The referential value is clearly noted as it is a referential one and the referential shape is drawn with no dimension in order to keep the state that one needs to refer to original drawing directly. Like this, one element is limited in only one place in whole drawing system in order to increase the accuracy of information.

-The functional design elements are included in the values or shapes of drawing and it's impossible to divide these elements from drawings.

- Drawins can present various design knowledges, like the direction of dimension arrows.

- Because each drawing is divided physicaly, it's easy to adjust parallel works with multi-worker. On the other side, high ability is required for every worker to keep the relations between drawings manually.

- This drawing-based design method is systemized smartly, like re-use of previous ship design, modification, correction, series design.

Above all, the drawing design system makes the environment where multi-worker can work smoothly by dividing and structuring design time, design layer, design space and designer by unit of drawing. Furthermore, pencil and paper can realize this environment at least.

Now, only the advantages of 3DCAD are focused. We should recognize the fact that we lives in the hobitable and optimized design environment.

3. Characteristics of 3DCAD

Usually our foucs tends to be put on the treatment of 3D-shapes, as the name of "3DCAD". In fact, the most important matter is that all of the necessary design data are built on computer databases. This design data built on one database or some databases that are linked by networks as to one database allows 3DCAD to show its maximum ability. In short, the present usage of 3DCAD in many shipyards, we use it for each calculation or work partly on the drawing-based design system, is not essencial.

Main characteristcs of 3DCAD are below;

- Concentrated design data

In the traditional drawing-based design system, persons must trace drawings to collect the necessary data for producing shapes. In 3DCAD system, it's possible to get all necesary data in required form instantly, and various caluclations and works get much faster and much accurate. So we can adopt new calculations and works for design that was impossible with the limitations of cost and time before.

- Elimination of human factors from design elements

In the traditional drawing-based design system, persons must collect, read, translate and connect the various design elements that scatters on many drawings. These human factors among design elements makes the working time longer, the risk higher and the required ability for workers higher.

However, the concentrated data eliminates human factors from design elements. This reduces both the risk of human error and the required ability for workers low.

- New working environment

Until now, many techical limitations made us to work in the stereotyped design environment with traditional type and classification of drawings. However, the functions of databases lets us to work in new design environment like that Hull and Outfit designers work together in one block section. (Matrix approach)

4. Hurdle of 3DCAD

There are some hurdles to introduce 3DCAD.

- Low flexibility of system from direct relations between elements

The structure that design elements are related to each other tightly and directly makes the parallel work using the same design element impossible. In the drawing design system, we can work flexiblely, like that we do lower design with prediction before the upper design completes. Other exapmle, when the design mistake is appeared in production process, we can correct the product directlly before correcting the design drawings. However in 3DCAD, the replacement of these parallel work and reversed order work are needed. Especially, the joint ownership of design data between Functional design and Productional design must be studied sufficiently.

- Un-usability of exsisting methods and knowhows

Many methods and knowhows that have been heaped for long time in the drawing-based system are useless in 3DCAD. For example, the arrow-direction of drawing is not able to be presented on shape definition in 3DCAD. Various methods like design, input, check and education must be re-established because many interfaces are much different between drawing and 3DCAD.

- Treatment of Functional design element

In drawing-based design system, the functional design elements are consisted as a part of product shape. They are extracted from shape by designers who mediates between drawings and presented in designer's head. Like this, functiona design elements exists virtually in drawing system.

However, the extraction of functional design elements is getting more difficult because 3DCAD eliminates human mediators. So, we must change design standards or class rules to treat shapes directlly, or we must change 3DCAD to define functional design element. Or, the human work to read and translate the functional design element is needed, and the merit of 3DCAD decleases.

- Devising new design method and environment

Design method and environment are complex by themselves, and it's very difficult to analize and reconstruct them. Completeness of the previous system makes the hurdle of this problem higher.

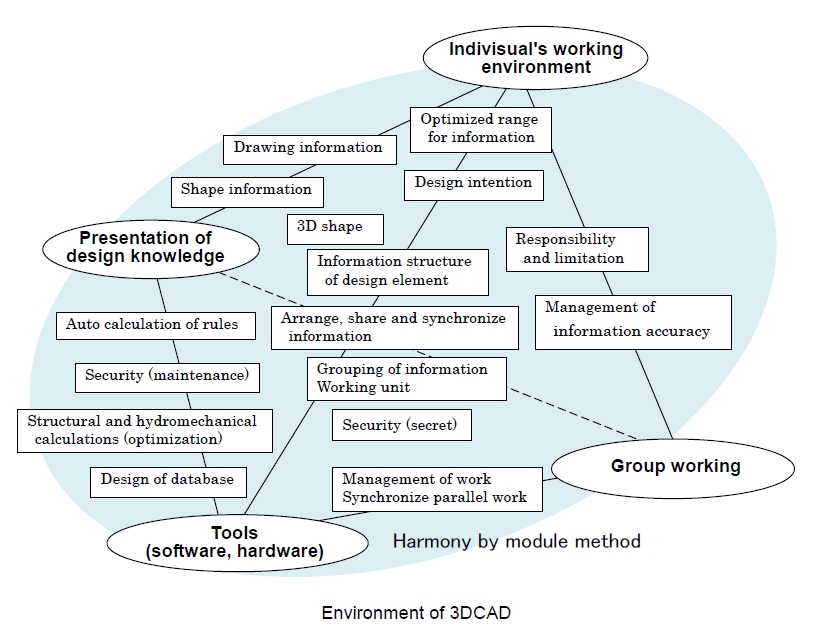

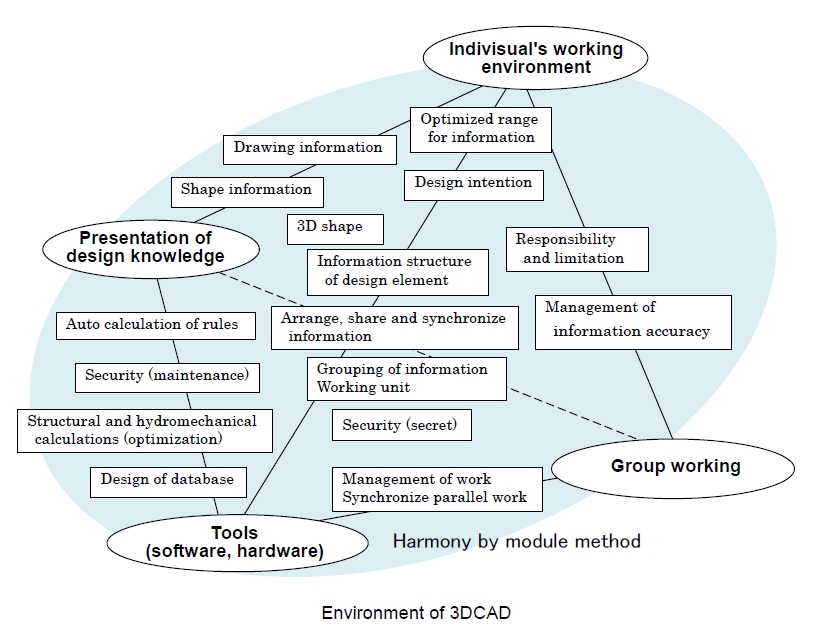

Especially in Japan, only presentation of design knowledge and computer technique are focused. Lack of sociological view, like group's cooperative working and lack of human science view, like indivisual's working environment disturb the introduction of 3DCAD.

- Adjustment with surrounding environment

Because the design method is related not only to shipyards but also to class, ship-owners, outfitting makers and subcontractors, it's necessary to adjust with them.

Class rule is the largest matter. The present class rules optimized for drawing-based design system must be change to be useful with 3DCAD.

5. Present situation of 3DCAD introduction, and problems

Now, no shipyard has introduced 3DCAD to all over range that is from top to bottom really. The wide range of work crossing many companies and sections and the long history of devided work make the project so huge. As a result, many shipyards are keeping the drawing-based design system and have introduced 3DCAD in each part of it.

There are some movements to make a new design information format that can be shared in much wider range than now, too. U.S.Navy's LEAPS is the most progressive one, and Japanese ship class NK is studying the format to calculate class rules now although its size and level is much lower than U.S.Navy's. Of course, introduction of 3DCAD in the range after detailed design is being driven by many shipyards in all the world.

The relational area of introduction is so wide that it's very difficult to change the design method on it, and this is the same to the national large project or one shipyard's tiny project. It's not just easy matter to change writing tool from a pencil to an automatic pencil.

The strong organization to drive changes must be needed, of course. It's necessary to notice its necesity, organize it and then execute the changes following it, as soon as possible.